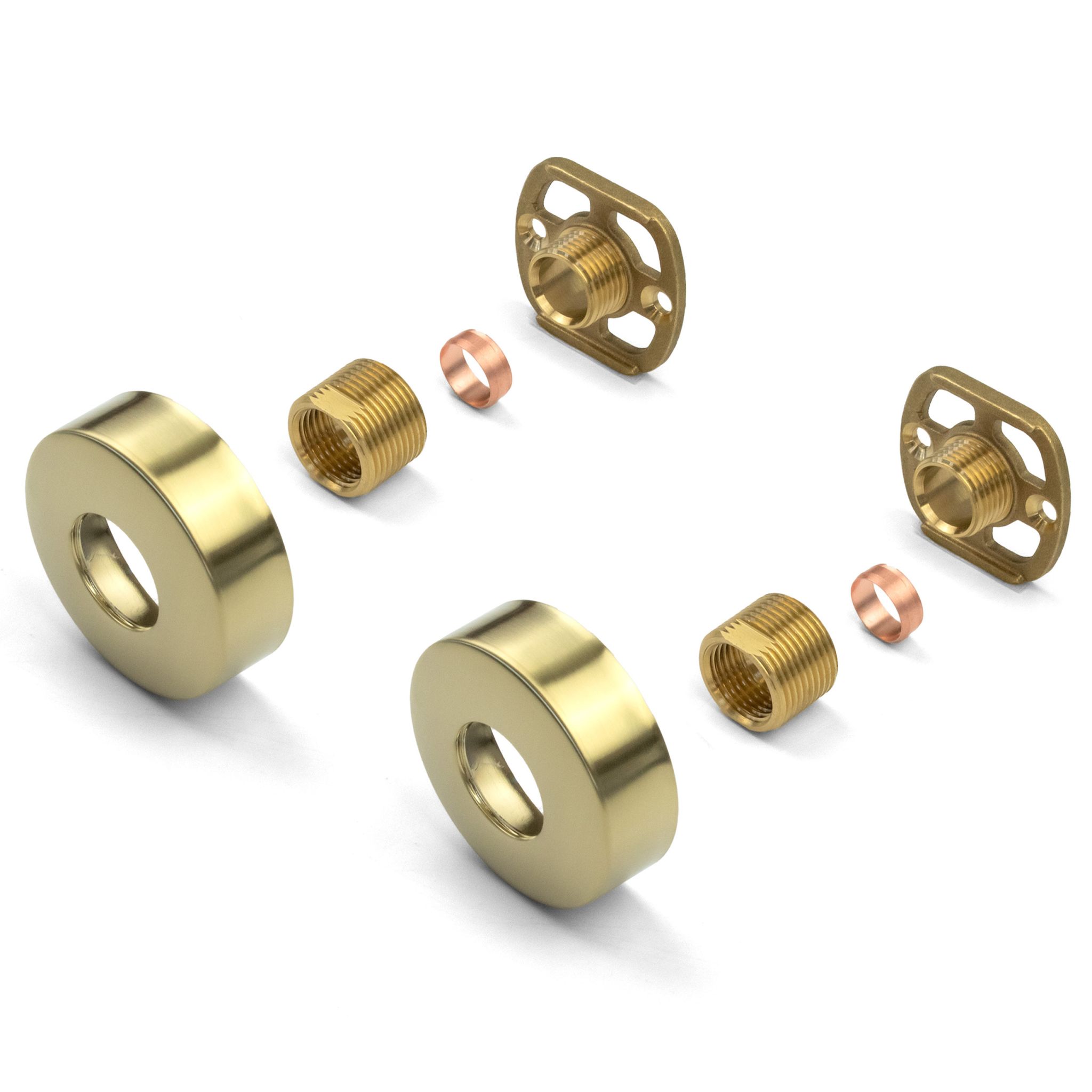

Fixing Plates Connectors

Durable Fixing Plates & Connectors by OeTaps

Welcome to DM Wholesale Services Limited UK, your premier destination for high-quality building and plumbing accessories. Our collection of fixing plates and connectors from OeTaps is designed to provide superior support and stability for your installations. Whether you’re a professional tradesperson or a DIY enthusiast, our range ensures you get the best in terms of quality, durability, and performance.

Crafted from high-quality materials such as stainless steel, brass, and durable plastics, our fixing plates and connectors are built to withstand the rigors of daily use. The robust construction ensures long-lasting durability, providing you with peace of mind knowing that your fixtures are securely anchored in place.

Our range includes a variety of fixing plates and connectors to suit different applications and requirements. From standard backplates and flanges to specialized mounting brackets and support arms, we offer options that cater to various installation scenarios, ensuring a perfect fit for your specific needs.

Installation is quick and straightforward with our user-friendly designs and comprehensive instructions. Whether you’re a DIY enthusiast or a professional installer, our fixing plates and connectors are designed for easy setup, saving you time and effort during the installation process.

Here are the features, benefits, and safety considerations associated with fixing plates and connectors:

Features:

- Material Variety: Fixing plates and connectors are typically made from sturdy materials such as steel, stainless steel, aluminum, or plastic, ensuring durability and strength in various applications.

- Versatile Designs: They come in a variety of designs and configurations to accommodate different joining needs, including flat plates, corner braces, angle brackets, T-plates, mending plates, and more.

- Mounting Holes: Many fixing plates and connectors feature pre-drilled or punched mounting holes, making them easy to install using screws, bolts, or nails. Some designs may also include slots for adjustable positioning.

- Strength and Stability: Fixing plates and connectors are engineered to provide strong and stable connections between materials, ensuring structural integrity and preventing joints from loosening or failing over time.

- Corrosion Resistance: Depending on the material and finish, fixing plates and connectors may offer resistance to corrosion, rust, and other environmental factors, prolonging their lifespan and maintaining their appearance.

Benefits:

- Enhanced Structural Support: Fixing plates and connectors reinforce joints and connections between materials, distributing loads evenly and reducing stress concentrations. This enhances the overall strength and stability of structures, furniture, and other assemblies.

- Easy Installation: Most fixing plates and connectors are designed for straightforward installation, requiring basic tools such as screwdrivers, drills, or wrenches. This simplifies assembly and saves time during construction or repairs.

- Versatility: With a wide range of designs and sizes available, fixing plates and connectors can be used in various applications, including wood-to-wood, wood-to-metal, and metal-to-metal connections. They offer flexibility and adaptability to different project requirements.

- Improved Aesthetics: Fixing plates and connectors can also contribute to the visual appeal of finished projects by providing neat and concealed connections between materials. Some designs feature low-profile or decorative finishes for a polished look.

- Cost-Effectiveness: By strengthening joints and preventing premature wear and tear, fixing plates and connectors help extend the lifespan of structures and furniture, reducing the need for frequent repairs or replacements. This can result in long-term cost savings.

Safety Considerations:

- Proper Installation: Follow manufacturer instructions and recommended guidelines when installing fixing plates and connectors to ensure secure and reliable connections. Use appropriate fasteners and tools, and avoid over-tightening screws or bolts, which can damage the materials.

- Load Capacity: Consider the load-bearing capacity of fixing plates and connectors relative to the intended application. Choose designs and sizes that can adequately support the anticipated loads to prevent structural failure or collapse.

- Material Compatibility: Ensure that fixing plates and connectors are compatible with the materials being joined, taking into account factors such as thickness, hardness, and composition. Using incompatible materials can compromise the strength and integrity of connections.

- Regular Inspection: Periodically inspect fixed joints and connections for signs of wear, damage, or loosening. Replace or reinforce fixing plates and connectors as needed to maintain structural stability and prevent accidents or injuries.

- Sharp Edges: Be cautious of sharp edges or protrusions on fixing plates and connectors, which can cause cuts, scrapes, or snagging hazards during handling or use. File or smooth down rough edges to minimize the risk of injury.

By understanding the features, benefits, and safety considerations of fixing plates and connectors, builders, craftsmen, and DIY enthusiasts can make informed decisions when selecting and using these components in their projects, ensuring strong, reliable, and safe connections.